"Nanjing Jufa New Materials Unveils Cutting-Edge Polyurethane Resins at the 2025 Shanghai PV Expo"

2025/06/16

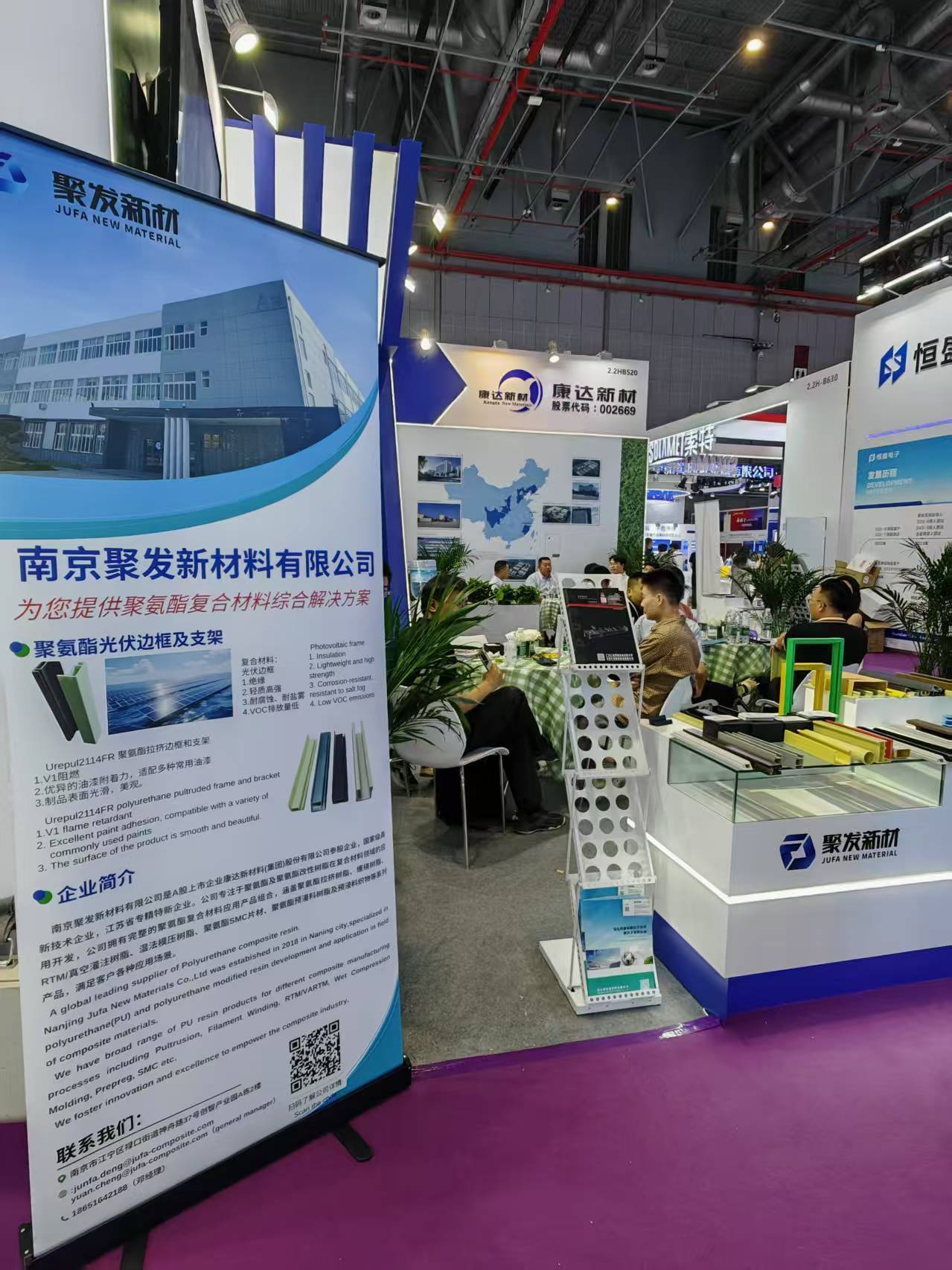

In June 2025, the SNEC International Solar Photovoltaic & Smart Energy Conference (SNEC 2025)—a premier global event in the photovoltaic industry—successfully concluded in Shanghai.

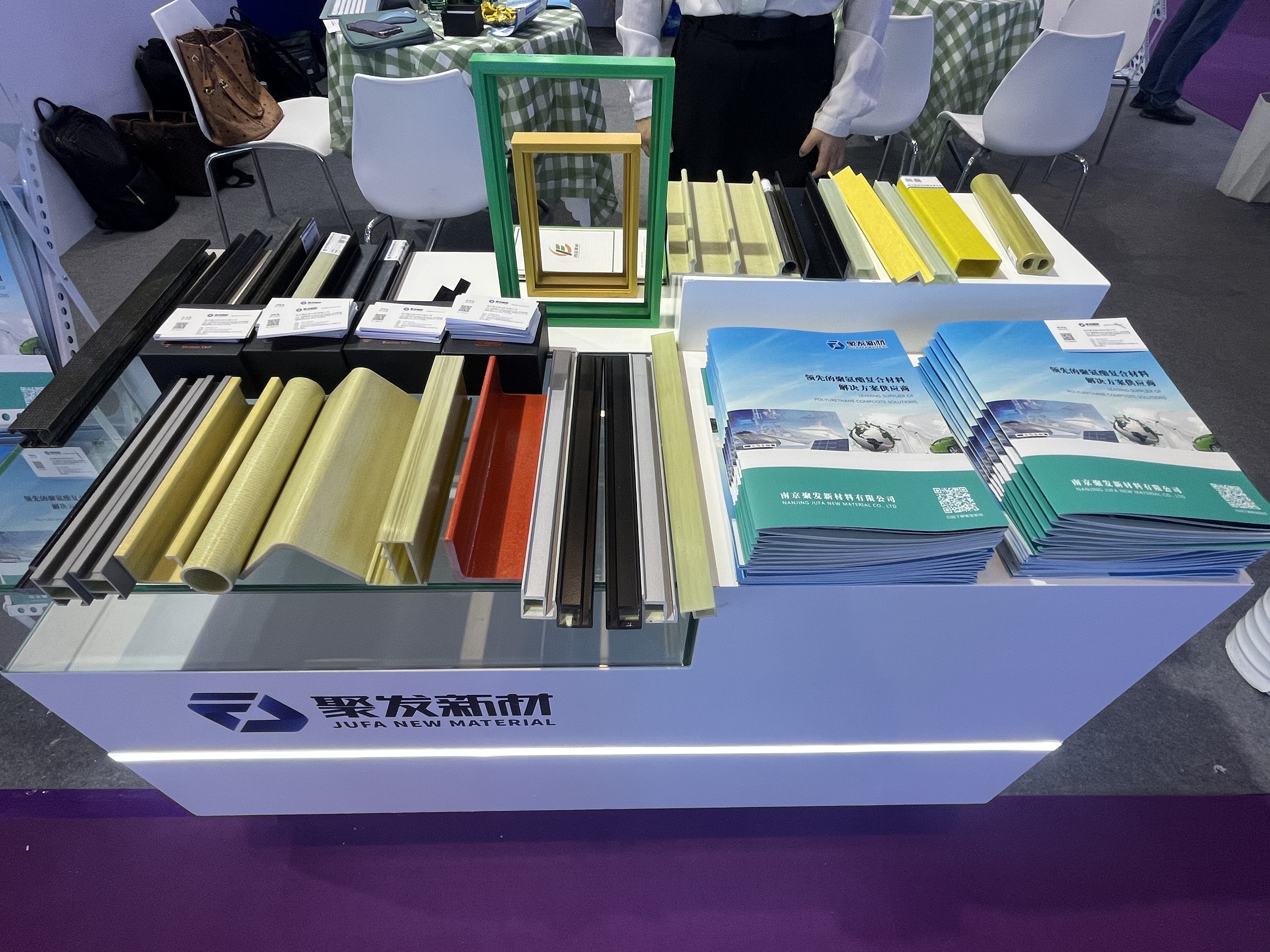

As a leading supplier of high-performance polyurethane resins, Nanjing Jufa New Materials Co., Ltd. made a remarkable appearance by showcasing its specialized polyurethane resin series for photovoltaic applications. The exhibition highlighted the innovative use of polyurethane resins in critical areas such as PV modules and frames, drawing significant attention from industry leaders and professionals in the composites sector.

I. Innovative Breakthrough: Polyurethane Resin Offers New Solutions for PV Modules

At the exhibition, our company's featured photovoltaic-grade polyurethane resin series products became a focal point due to their outstanding performance:

Urepul 2114FR-GL (Aromatic Resin) & Urepul 2228FR (Aliphatic Resin):

Certified byTUV - SUD , a globally recognized authority

Specifically designed for PV module frame bonding

Exceptional adhesion strength and weather resistance

Enhances structural stability in extreme environments, extending service life

Optimized production processes help customers increase efficiency and reduce costs

Urepul 2114FR:

Excellent processability and paint adhesion

Outstanding tensile strength, flexural strength, and impact resistance

Ensures consistent production quality and long-term weathering reliability

Urepul 2228FR:

Mechanical properties comparable to aromatic polyurethane, with superior adhesion & weather resistance

Demonstrates unique advantages in PV and marine engineering applications:

PV Industry: Ensures stable long-term operation under harsh outdoor conditions, improving energy efficiency and lifespan

Marine Engineering: Withstands saltwater corrosion, wave impact, and extreme marine climates—making it ideal for:

Offshore wind power installations

Marine platform protection

Other critical composite material applications

Drives the composites industry toward safer, more efficient, and sustainable development

II. Technology Exchange: Exploring Future Potential of Polyurethane Resins with Industry Partners

During the exhibition, our sales, R&D and technical teams engaged in in-depth discussions with global module manufacturers, material suppliers and research institutions. The exchanges focused on:

Future development trends of polyurethane resins in photovoltaic applications

Technical advantages and industrialization achievements of our resin solutions

Customized material solutions for diverse application scenarios

The discussions generated enthusiastic responses from participants. Multiple clients acknowledged that Jufa New Materials' polyurethane resins not only demonstrate outstanding performance, but also offer customized services to meet specific application requirements. This combination provides the photovoltaic industry with more competitive material solutions that address real-world challenges.

III. Collaborative Win-Win: Jointly Promoting Green Transformation in PV Industry

Through this exhibition platform, our company has reached strategic cooperation intentions with several composite material enterprises in the PV module sector. Together, we will advance the large-scale application of polyurethane resins in high-efficiency modules, while committing to develop next-generation environmentally friendly polyurethane resins to further reduce the carbon footprint of the photovoltaic industry.

At the exhibition site, our General Manager stated: "As an emerging material in the photovoltaic field, polyurethane resin possesses broad application prospects. Jufa New Materials will continue to increase R&D investment and collaborate with industry partners to drive innovation and technological upgrading in PV sector."

Nanjing Jufa New Materials Co., Ltd. specializes in the R&D and production of high-performance polyurethane resins, with products widely applied in photovoltaic, building fenestration, automotive and other industries. Equipped with state-of-the-art R&D centers and production bases, the company is committed to delivering high-quality, highly reliable material solutions to global customers.