Composite wind turbine blade technology and market analysis

2024/04/16

01 Introduction

With the development of large-scale wind turbines, lightweight design requirements become more and more prominent. The ultra-long blades of 15MW wind turbines put forward higher requirements for the strength, stiffness and fatigue resistance of materials, which provides a premise for the batch application of carbon fiber composite materials in the field of wind power blades. The mechanical properties of small tow carbon fiber are excellent, but due to cost factors, the large-scale promotion and application in the field of wind power blades has been stagnant, and the development of large tow carbon fiber in the past decade has precisely embarked on the rapid growth of global wind power composite blades. In 2022, the amount of wind power blade carbon fiber is as high as 34,700 tons, accounting for 25.7% of the global carbon fiber consumption, according to the forecast that the demand for carbon fiber in the wind power industry is still strong in the next decade, and it is expected to reach more than 195,000 tons by 2030, wind power sheet manufacturing enterprises are putting forward urgent requirements for the price of low-cost carbon fiber.

02 Demand for composite materials for wind power blades

The longer the size of wind power blade, the greater the overall flexible deformation. It is necessary to control the deflection deformation of blade tip during operation to ensure the safe distance between blade and tower, otherwise tower sweeping accidents will occur.

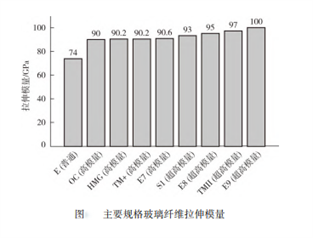

Glass fiber is currently the largest amount of wind power blade main beam raw materials, according to statistics, wind power blade glass fiber consumption accounts for 20% to 25% of China's total glass fiber production capacity. The tensile modulus of glass fiber is one of the key factors affecting blade deformation, and the ultra-high modulus glass fiber is of great significance for improving blade stiffness. In the past 10 years, glass fiber enterprises have developed various specifications of glass fiber through continuous technological innovation. As can be seen from the figure, the modulus of each generation of glass fiber has increased by about 10%, and the modulus of ultra-high modulus glass fiber/epoxy pultrusion sheet has also reached 70Gpa. These advances have strongly promoted the development of large-scale wind power blades, and the current blade design with a length of less than 80m is basically based on glass fiber material system.

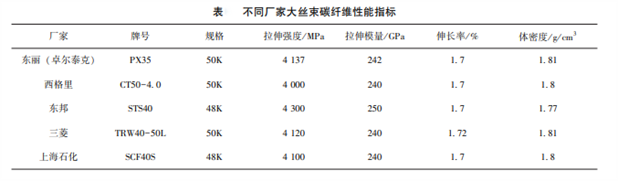

The tensile modulus of ultra-high modulus glass fiber has reached about 90% of the theoretical value, which can no longer meet the requirements of developing larger size offshore wind power blades. The tensile modulus of carbon fiber is 3 to 10 times higher than that of glass fiber, and the proportion is 30% smaller, which has obvious advantages in the design and manufacture of large-size wind power blades. With the increase of blade size and weight, in order to improve stiffness and fatigue resistance, the use of carbon fiber instead of glass fiber has become an inevitable choice, but the price of carbon fiber is usually 8 to 15 times that of glass fiber, taking into account cost factors, some wind turbine blade manufacturers length 80 to 120m wind turbine blades using carbon fiber/glass fiber (carbon glass) hybrid structure, Wind turbine blades with a length of more than 120m are made of pure carbon fiber composite materials (see table below).

Carbon glass hybrid pultrusion sheet of wind turbine blades can be adjusted according to the actual use conditions and cost factors of carbon glass hybrid ratio (ratio of volume fraction of carbon fiber and glass fiber), for example, the carbon glass hybrid pultrusion sheet produced by a domestic enterprise has two specifications of 1:2 and 2:3. Germany Repower company, Denmark LM company, Siemens Gamesa, Mingyang intelligent part of the wind turbine blade main beam plate are using carbon glass hybrid structure.

03 The rise of carbon fiber wind power blades

With the development of offshore high-power wind turbines, larger blades have become the only way, and the current length of blades above 120 m must be designed with carbon fiber sheets (carbon plates). The wind power blade prepared by carbon plate not only has excellent mechanical properties, but also is more energy saving and emission reduction. Taking the 3MW wind power turbine as an example, the total CO2 emission reduction of the carbon fiber composite blade is greater than 1000 tons compared with the glass fiber composite blade. The CO2 emission reduction effect of carbon fiber composite blades is more significant.

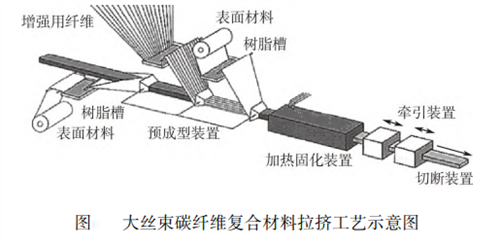

At present, the forming process of carbon plate of wind turbine blade is gradually solidified into pultrusion forming technology. Large tow carbon fiber composite pultrusion molding process has become the mainstream, and its specific process flow is shown in the figure. The main body of the equipment includes yarn frame and yarn guide device, resin tank, preforming device, heating and curing device, traction device, cutting device, and supporting winding device, control system, safety protection device and alarm device.

04 Market Outlook

From 2021 to 2022, the development of wind power market is relatively depressed, the data of the wind energy Professional Committee of the China Renewable Energy Society show that: in 2022, the national new wind power hoisting capacity fell by about 11% year-on-year, of which offshore wind power fell by more than 60% year-on-year. However, since the end of 2022, the construction of wind power projects around the country has gradually resumed, the construction of the western onshore and eastern offshore wind farms, the bidding is in full swing, the major main engine plants and matching plants are expanding capacity and capacity, it is predicted that by the end of 2023, the national matching wind power blade plate pultruding production line will reach 2,500. China Electricity Council released the "2023 National power supply and demand situation analysis Forecast Report" is expected that the new installed capacity of wind power in 2023 will reach 65 million kW·h, compared with 2022 a huge increase. With the gradual release of the production capacity of large-tow carbon fiber under construction and the continuous progress of new low-cost and high-efficiency automated preparation technology, glass fiber sheet, carbon fiber sheet and new low-cost resin system sheet will form a sub-track competition situation in the application of wind power blades of different powers, and the cooperation of raw materials, technology development, production and application will become more and more close. China's wind power industry in the next 5 to 10 years will have a larger scale explosive growth.