"Innovative Applications of Polyurethane Resin in Composite Material Manufacturing"

2025/05/23

Polyurethane resin and composite material process

1. Composite materials are composed of two or more chemically and physically different material components, which are combined in a designed form, proportion, and distribution, with distinct interfaces between the components;

2. Composites have structural designability, allowing for composite structure design; they not only maintain the advantages of the properties of each component material but also achieve comprehensive performance that cannot be reached by single-component materials through the complementarity and interaction of their properties.

Polyurethane pultruded composite materials have been widely applied in various industries.

Polyurethane composite material performance characteristics

Advantages of Polyurethane Composite Materials

Replacing unsaturated resins and epoxy resins: higher strength and toughness, higher production efficiency, lower cost, excellent flame retardant properties, environmentally friendly production environment. Replacing metals such as aluminum alloy: lightweighting, corrosion resistance, better durability.

Environmental Protection and Sustainability

Material Performance Comparison

Cost and Process Comparison

Typical Application

Fields New Energy Field:

Polyurethane extrusion process - photovoltaic frame/bracket

For a long time, photovoltaic power stations have been using traditional metal frame components. However, under the long-term action of high voltage, PID (Potential Induced Degradation) effect occurs in these components, leading to fatal power attenuation and a sharp decline in power generation, causing significant economic losses. Therefore, there have been rounds of attempts within the industry to develop solutions to reduce the risk of PID effects. Non-metal frames may be a very good solution.

Advantages of polyurethane photovoltaic frames/supports:

1. Lightweight design

With a density of only 2.1 g/cm³ (30% lighter than aluminum alloy), it reduces transportation energy consumption and installation complexity, suitable for weight-sensitive scenarios such as rooftop photovoltaics (BIPV) and floating power stations.

2. Thermal Expansion Compatibility

The coefficient of thermal expansion is consistent with that of photovoltaic glass (about 9×10⁻⁶/°C), reducing the risk of component deformation, seal failure or glass breakage due to temperature difference, and improving long-term reliability.

3. High insulation

The natural insulation characteristics avoid PID (potential induced degradation) risks, eliminating the need for additional grounding measures and simplifying system design while improving power generation efficiency by reducing electrical energy loss by 5% to 10%.

4. Environmental protection and low-carbon development

The carbon emissions from the production of single GW are only 0.23 tons (approximately 1.5 times that of aluminum alloy), meeting the requirements of ESG and carbon neutrality; it can be physically recycled and reused, with great potential for the circular economy.

5. Excellent mechanical properties

The bending resistance strength reaches 800 to 1200 MPa (3 to 5 times that of aluminum alloy), with strong impact resistance. It is suitable for areas with high loads or strong winds, reducing the risk of structural failure.

6. Cost-benefit optimization

Initial cost: The current price is 20% to 25% lower than that of aluminum alloy, and the acceleration of domestic production of raw materials helps to further reduce costs.

Life cycle cost: Maintenance-free, long-life design. The total cost over 25 years is 10% to 15% lower than that of aluminum alloy.

7. Flexible scene adaptation

Compatible with processes such as pultrusion and compression molding, it can customize the production of special-shaped structures to meet diverse demands in offshore photovoltaic power generation, agricultural photovoltaic integration, and high-latitude projects, accelerating the replacement of traditional metal frames.

Advantages of Guifa New Materials' Spray-Free Resin:

Jufa New Materials' aliphatic polyurethane resin, through material innovation, has addressed the problems of traditional resins, such as "weather resistance relying on post-treatment" and "difficult to balance mechanical properties", providing more efficient and sustainable solutions for outdoor high-load scenarios like photovoltaics and marine engineering.

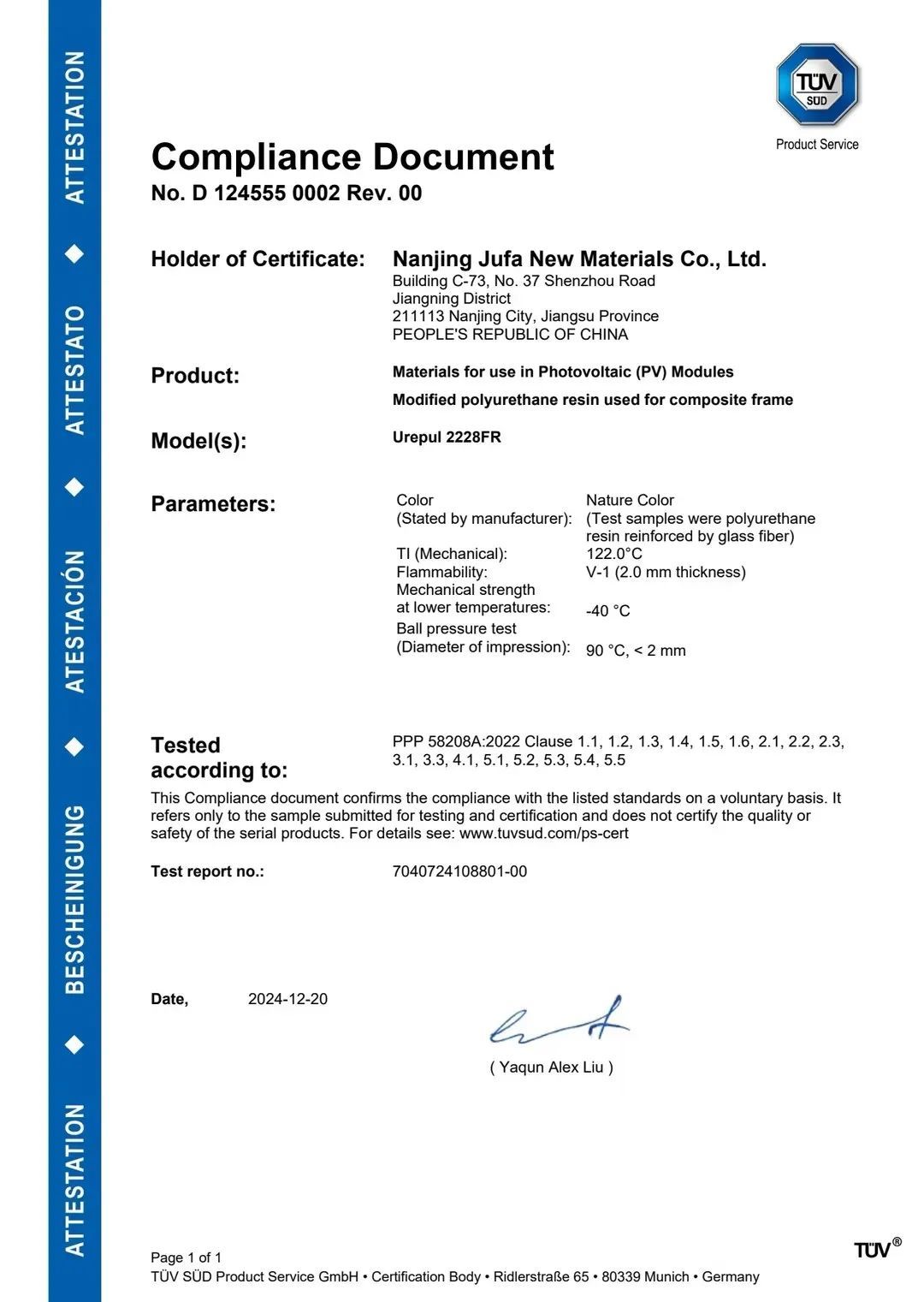

1.Advantages of UV resistance and no need for painting

Traditional aromatic resins are not resistant to ultraviolet rays and thus require a protective layer to be sprayed later (such as polyurethane paint) to extend their lifespan, which increases the complexity of the process and the cost. However, the aliphatic polyurethane pultrusion resin from Polyflex New Materials has passed TUV-SUD certification. Its molecular structure possesses natural UV resistance, and it can maintain stable physical and chemical properties even when exposed to ultraviolet rays, humidity, salt spray, and temperature cycling for a long time. Its weather resistance directly matches that of polyurethane paint, eliminating the need for spraying, reducing processing costs while ensuring long-term aesthetics and functional integrity in outdoor scenarios.

2. Mechanical properties and high load-bearing compatibility

This resin not only breaks through the bottleneck of weather resistance, but also has core mechanical indicators such as tensile strength, bending strength and impact resistance that are comparable to those of aromatic polyurethanes. The bending strength can reach 800 to 1200 MPa, meeting the rigidity requirements of high-load scenarios such as photovoltaic frames and offshore wind turbine components. Moreover, it does not compromise mechanical properties due to weather resistance, achieving a dual balance of "strength - durability".

3. Enhancement of economic performance throughout the entire life cycle

Cost reduction and efficiency improvement: The no-spraying process shortens the production process, reduces processing energy consumption and labor costs.

Long-lasting maintenance-free: The anti-aging property extends the service life of the components (estimated to increase by more than 30%), reducing the costs of replacement and maintenance due to corrosion and cracking.

Environmental compliance: Avoid VOC emissions during the spraying process, in line with green manufacturing standards.

Construction field:

Polyurethane pultrusion process - Polyurethane energy-saving doors and windows

The traditional window and door profiles consume a large amount of energy during application and have poor fire resistance, which no longer meets the requirements of green buildings. The polyurethane composite material pultrusion profiles represent the inevitable trend for the development of energy-saving window and door profiles in the future.

Glass Fiber Reinforced Polyurethane (abbreviated as GRPU) is a high-performance composite material. It is produced through injection, impregnation and extrusion processes. Due to its fiber reinforcement, its compressive, tensile and bending strength are all very high.

Ultra-low heat conduction - Super energy efficiency

This system does not require any breakaway joints or steel liners. The thermal conductivity of its profiles is excellent: when the entire window design has a K value of 2.0, the energy-saving performance of this system's double-glazed glass exceeds that of the triple-glazed glass made of aluminum alloy. When combined with three layers of glass, it can meet the standard of a passive house with a K value of 0.9W/m2•k.

2. Reliable low-temperature resistance capability

The glass fiber reinforced polyurethane pultrusion profiles have passed the physical performance comparison test of being frozen and thawed 100 times at -40℃, ensuring their mechanical properties in extremely low temperatures.

3. Excellent mechanical properties

Continuous fibers significantly enhance the strength, hardness and elastic modulus (bending modulus can reach 51 GPa) of polyurethane profiles. Without the need to insert reinforcing steel, stable hollow glass bearing can be achieved.

4.A longer service life

Compared to thermoplastic materials such as polyamide and polyvinyl chloride, fiberglass-reinforced polyurethane pultruded profiles not only have the advantage of load-bearing but also possess superior aging resistance and corrosion resistance, thus having a longer service life (up to more than 50 years).

Electric power field

Polyurethane winding process - Polyurethane wound poles, 5G communication towers

The use of polyurethane winding composite material technology to manufacture electric poles and 5G communication towers has the advantages of being lightweight (convenient for installation and transportation), high strength (long lifespan), corrosion resistance (less maintenance), low product cost, and environmentally friendly manufacturing process. It solves problems such as heavy weight of metal towers, difficulty in installation and transportation, large occupied area during installation, need for annual maintenance due to corrosion, and environmental pollution during production. It reduces system costs and improves product quality.

High-pressure RTM process

Rail transit field, new energy vehicle field

Polyurethane SMC

Product Advantages (Compared to Unsaturated, Vinyl, and Epoxy)

1. High strength, high modulus, low shrinkage, low VOC

2. Good insulation, durability

3. Lower cost compared to vinyl and epoxy systems

Polyurethane Prepreg

Product Advantages (Compared to Epoxy Resin)

1. High strength, high modulus, excellent flame retardant properties

2. Compared to epoxy, it can be stored at room temperature for a long time without the need for a cold storage; rapid curing at high temperatures, easy demolding, and high efficiency

聚氨酯湿法模压

Advantages of Polyurethane Resin (Compared to Epoxy Resin)

1. Higher strength and better flame retardant properties

2. Faster wetting speed and curing, better processability

3. Lower cost

Jufa New Materials - Leading Supplier of Polyurethane Composite Material Solutions

** Contact us ** : Tel: +(86)18068807638 (Ms. Chen) | Email: sales3@jufa-composite.com

Tel: +(86)17316334513(Mr. Cheng) | Email:yuan.cheng@jufa-polyurethane.com