**Unlocking the Advantages of Polyurethane Fiber-Reinforced Doors and Windows**

2025/05/27

Driven by the "dual carbon" strategy, building energy conservation is advancing from structural design to material innovation in depth. Polyurethane composite materials, with their lightweight, high-strength, weather-resistant, and corrosion-resistant properties, have been widely used in high-end fields such as aviation and wind power. However, their potential in the field of building doors and windows has not been fully exploited for a long time. In response to the extreme climate characteristics of high temperature, high humidity, high salt content, and frequent typhoons in Hainan, the "Technical Standard for External Doors and Windows of Civil Buildings in Hainan Province" has set strict requirements for the performance of doors and windows: the wind pressure resistance must reach the highest national standard level (Grade 9), the corrosion resistance life must exceed 30 years, and an ultra-low energy consumption target must be achieved. Traditional aluminum alloy doors and windows, due to high carbon emissions, low insulation, and susceptibility to corrosion, have been unable to meet the demands. However, glass fiber reinforced polyurethane doors and windows have broken through the bottleneck with disruptive technology:

Anti-tropical cyclone: The wind pressure resistance performance meets the highest national standards, enabling it to handle 12-level typhoons with ease.

Corrosion-resistant: Does not rust in high-salt environments, and has a much longer service life than aluminum alloy.

Strong sound insulation: ≥ 42 dB (close to the standard of a silent room)

Waterproofing: Unique structural design + high airtightness, even on rainy days, the interior can remain dry.

The core technical advantages mainly lie in the following aspects

I. Material Properties

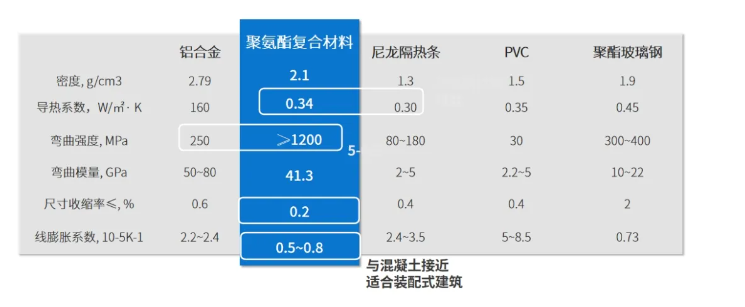

In the field of building materials, traditional aluminum alloy doors and windows have become a major obstacle to the industry's green transformation due to their high energy consumption and high carbon emission characteristics during the production and processing stages. In sharp contrast, glass fiber reinforced polyurethane profiles, through revolutionary technological innovations, have ushered in a new era of environmental protection for window materials:

Low-carbon production model: The carbon emissions during the production process are only 1/8 of those of aluminum alloy, and there is no need for energy-intensive electrolysis or melting processes. Glass fibers only require one melting process, and the energy consumption for the reaction of polyurethane resin is low.

Ultimate heat insulation efficiency: The thermal conductivity is as low as 0.34 W/(m²·K), only 1/470 of that of aluminum alloy, achieving "full insulation bridge" insulation effect, significantly reducing building operation energy consumption.

Lightweight and high-strength characteristics: The density of glass fiber reinforced polyurethane is 4/1 lighter than aluminum alloy, and its bending strength is more than 5 times. Based on this characteristic, the cross-sectional size of the profile can be reduced by 10%, not only achieving large-span transparent design, but also reducing energy consumption during transportation and installation.

Outstanding safety performance: The fire integrity of fiber polyurethane can reach 0.5-1.5 hours, and it carbonizes after burning; the failure temperature of glass fiber polyurethane is >1100℃, while the melting point of aluminum alloy is approximately 680℃. From the material perspective, glass fiber polyurethane is more suitable for fire-resistant windows.

Circular economy model: The production process has zero emission of volatile substances, and the waste can be recycled and reused, establishing a full life cycle closed loop from production to recycling, practicing the concept of green environmental protection.

Properties and parameters of glass fiber reinforced polyurethane materials

II. Processing Techniques

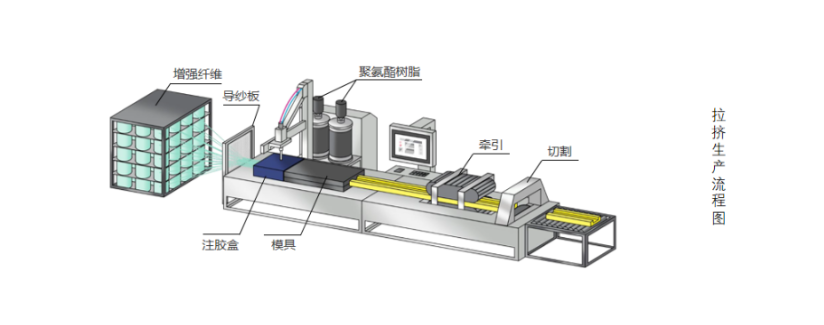

The processing technology of glass fiber reinforced polyurethane profiles focuses on "low energy consumption and high precision", and achieves the dual optimization of materials and structure through the pultrusion process:

Laminated molding technology: Glass fibers are introduced into the mold through the guide plate, and then polyurethane resin is injected and impregnated. After heating and curing, the fibers are pulled and molded. This process is a single-step molding, requiring no secondary processing. It has high production efficiency and a low waste rate.

Surface treatment innovation: The surface of fiberglass-reinforced polyurethane doors and windows is coated with water-based polyurethane paint, allowing for customized colors and textures. The special surface coating has a weather resistance lifespan approximately 1.5 times that of the aluminum alloy powder spraying process. The coating is corrosion-resistant and is particularly suitable for use in coastal areas with high corrosive seawater.

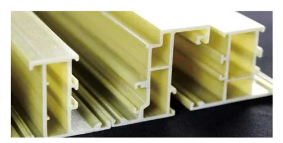

The aesthetic appearance of glass fiber reinforced polyurethane profiles

Non-processing coating: The extruded resin profiles produced by extrusion molding do not require any treatment before the surface coating. This ensures that the coating adhesion requirements are met, thereby reducing the processing procedures and lowering the coating cost.

Glass fiber reinforced polyurethane non-treated decorative profiles

III. Window Performance

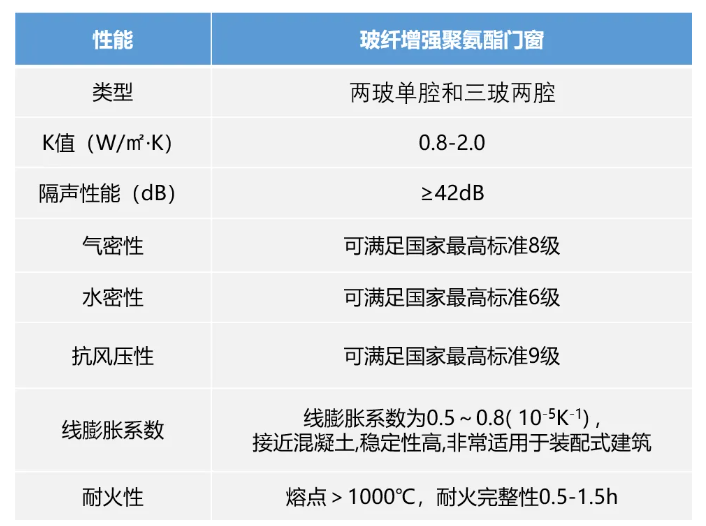

The overall window performance of fiberglass-reinforced polyurethane profile doors and windows breaks through the limitations of traditional materials, presenting six-dimensional advantages of "energy conservation, safety, comfort, durability, aesthetics, and environmental friendliness".

Energy-saving and thermal insulation leadership: The overall window heat transfer coefficient K value starts at 2.0 W/(㎡·K) and can be as low as 0.8 W/(㎡·K), with excellent insulation performance and easily meeting the standards for ultra-low energy buildings.

Sound insulation and air tightness: Sound insulation performance is ≥ 42 dB, and air tightness and water tightness can meet the highest national standards, effectively blocking noise, air and water vapor penetration.

Wind pressure resistance and corrosion resistance: Wind pressure resistance reaches the highest national standard, resistant to salt spray, acid and alkali, and extremely suitable for coastal cities and harsh industrial environments.

Fire safety upgrade: Combined with fire-resistant glass, it can achieve 1-hour fire integrity, breaking through the bottleneck of traditional window fire resistance performance.

The performance of fiber-reinforced polyurethane windows

IV. Application and Cost

With the iterative improvement of the pultrusion process and the advancement of large-scale production, this material has overcome the cost barrier in the field of doors and windows. Currently, due to various factors such as rising raw material costs, changes in supply and demand, and policy influences, the price of aluminum profiles has continued to rise. The price of glass fiber reinforced polyurethane profiles has become similar to that of aluminum profiles, and in applications with high energy-saving requirements, the cost is even lower than that of aluminum profiles.

In addition to doors and windows, glass fiber reinforced polyurethane composite materials can also be applied to photovoltaic frames, curtain walls, and frame attachments. Their application scenarios are extending from high-end manufacturing to civilian buildings, reshaping industry standards with "super performance + low carbon cost".

Fiber-reinforced composite doors and windows, as an innovative application of composite material technology, integrate lightweight, functionalization and sustainability, demonstrating the innovative direction of modern building materials. Its core advantages lie in: at the material level, through the collaborative design of high-strength fibers (such as glass fibers and carbon fibers) and resin matrix, while maintaining light weight (with a density only one-fourth that of steel), it achieves superior wind pressure resistance and impact resistance compared to traditional metal doors and windows, and has a thermal expansion coefficient that matches the wall, significantly reducing the risk of sealing failure; at the manufacturing level, relying on efficient molding processes such as pultrusion and compression molding, it can produce multi-chamber structures in one step, reducing joint nodes, and increasing air tightness by more than 50%, and supporting customized and irregular design; at the sustainability level, the energy consumption throughout the life cycle is reduced by 60% compared to aluminum alloy, the corrosion resistance (salt spray test ≥ 4000 hours) and anti-aging property (lifetime over 50 years) significantly reduce maintenance costs, and in combination with the recyclability of thermoplastic composite materials (reutilization rate > 80%), it meets the requirements of the "dual carbon" strategy. Such products not only break through the performance bottlenecks of traditional building materials, but also promote the transformation of the construction industry towards high-performance, low-energy consumption, and intelligent manufacturing, becoming a benchmark example of composite materials empowering the real economy across multiple fields.