Why Glass fiber - reinforced polyurethane stands out in the competition of door and window profiles?

2025/07/24

In the field of architectural doors and windows, the choice of profile materials is directly related to performance, quality, and user experience. Today, with this "Performance Comparison of Glass Fiber - Reinforced Polyurethane Door and Window Profiles with Other Door and Window Profile Materials", let's have an intense competition of door and window profiles and see why glass fiber - reinforced polyurethane composite material stands out among a host of materials!

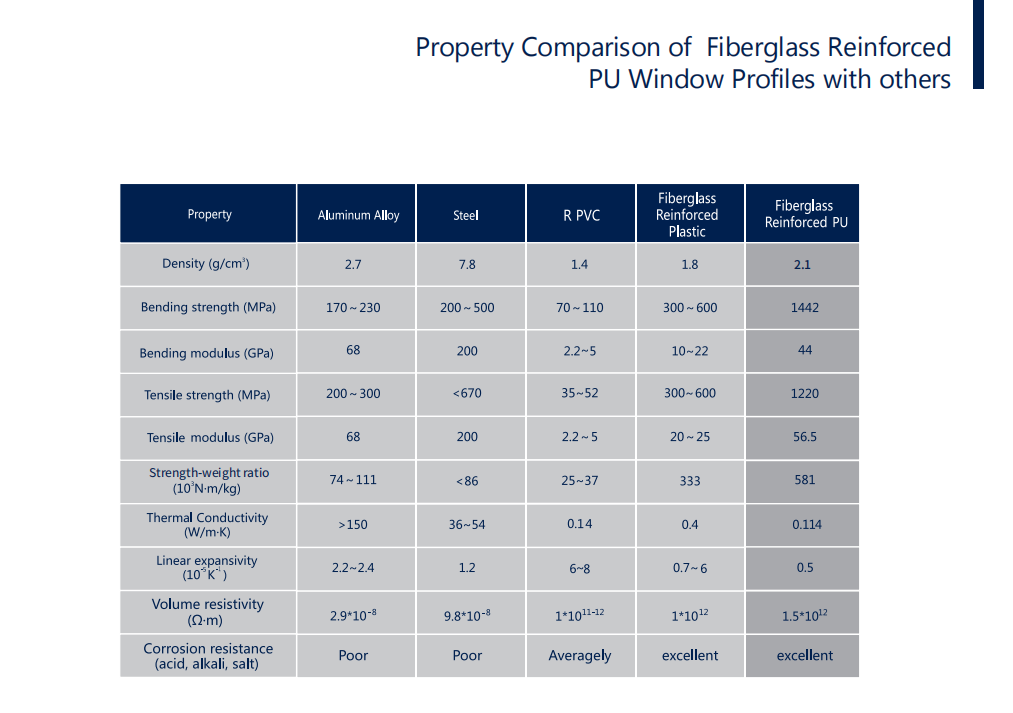

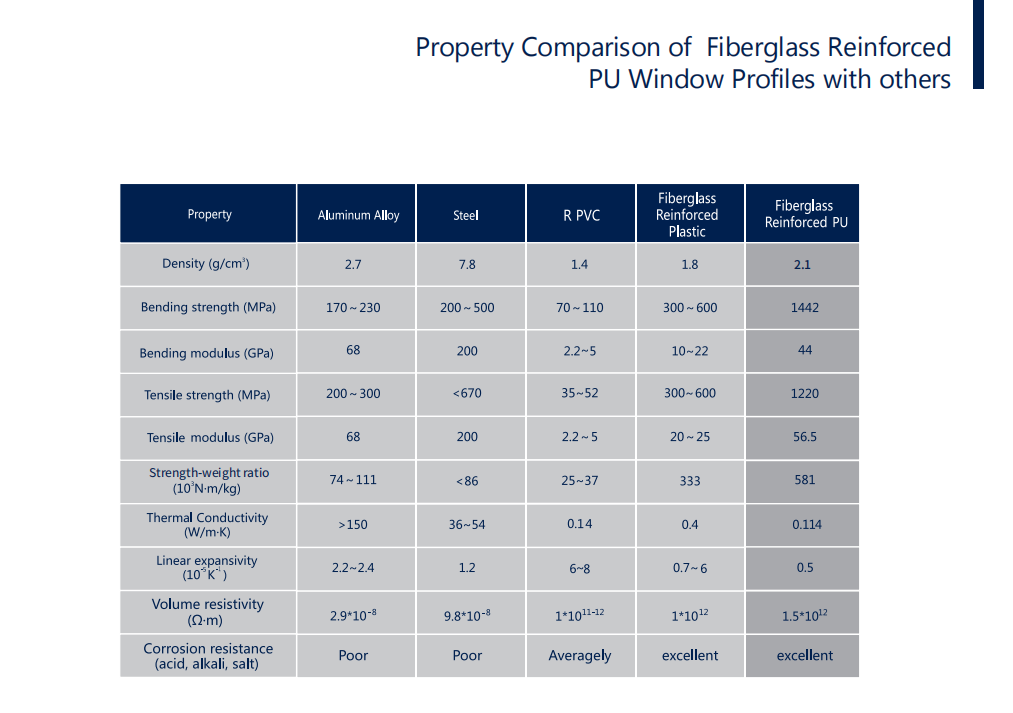

I. Basic "Physique" - Density Comparison

Density is the first "sense of weight" given by a material. The density of aluminum alloy is 2.7g/cm³, and that of steel is even as high as 7.8g/cm³. When held in the hand, they are heavy. When applied to doors and windows, they will put some extra burden on the building structure. The density of rigid PVC is 1.4g/cm³, which is quite light. The density of polyester glass fiber reinforced plastic is 1.8g/cm³, while the density of glass fiber - reinforced polyurethane composite material is 2.1g/cm³. Although it is not the lightest, combined with subsequent performances, this "weight" is just right. It not only ensures structural stability but also does not add too much pressure to the installation and the building. It is an excellent player in "body management".

II. Mechanical Properties - Hard - core Comparison of Strength and Modulus

(I) Bending Performance: The True Test of Bending Resistance

In terms of bending strength, the aluminum alloy is in the range of 170 - 230MPa, the steel is 200 - 500MPa, and the rigid PVC is only 70 - 110MPa. The polyester glass fiber reinforced plastic performs well, with a range of 300 - 600MPa. However, the glass fiber - reinforced polyurethane composite material directly soars to 1442MPa! What does this mean? It is like a group of people competing in bending down to carry heavy objects. Others wobble when carrying dozens or hundreds of catties, but it can steadily carry the pressure of over a thousand "catties". For the daily opening and closing of doors and windows and when encountering external impacts, this strong bending strength is like a "stabilizing anchor", without deformation or damage, and steadily safeguards the safety of use.

In terms of flexural modulus, the aluminum alloy is 68GPa, the steel is 200GPa, the rigid PVC is 2.2 - 5GPa, the polyester glass fiber reinforced plastic is 10 - 22GPa, and the glass fiber - reinforced polyurethane composite material is 44GPa. The flexural modulus reflects the ability of a material to resist bending deformation. The higher the value, the less likely it is to be bent. While ensuring a certain "toughness", the glass fiber - reinforced polyurethane composite material has good rigidity. When used for door and window frames and sashes, there will be no bending deformation after long - term use, and it always maintains aesthetics and functionality.

(II) Tensile Performance: The "Stubbornness" of Not Being Pulled Apart

In terms of tensile strength, the aluminum alloy is 200 - 300MPa, the steel is < 670MPa, the rigid PVC is 35 - 52MPa, the polyester glass fiber reinforced plastic is 300 - 600MPa, and the glass fiber - reinforced polyurethane composite material is as high as 1220MPa. Imagine treating the material as a "tug - of - war rope". This material can withstand super - strong tensile force. After the doors and windows are installed, regardless of wind, sun, thermal expansion, and cold contraction, the connection parts and the profile itself will not be "pulled apart", and the overall structure will be firmly maintained.

In terms of tensile modulus, the aluminum alloy is 68GPa, the steel is 200GPa, the rigid PVC is 2.2 - 5GPa, the polyester glass fiber reinforced plastic is 20 - 25GPa, and the glass fiber - reinforced polyurethane composite material is 56.5GPa. Its "elastic recovery force" during tensile stress is excellent. It can rebound well after being stressed without residual deformation. After long - term use of the doors and windows, there will be no relaxation or deformation due to repeated stress, and the durability is fully enhanced.

(III) Specific Strength: The "Cost - effective" Mechanical Advantage

Specific strength (the ratio of material strength to density) is the key to measuring the light weight and high strength of a material. The aluminum alloy is 74 - 111×10⁶N・m/kg, the steel is < 86×10⁶N・m/kg, the rigid PVC is 25 - 37×10⁶N・m/kg, the polyester glass fiber reinforced plastic is 333×10⁶N・m/kg, and the glass fiber - reinforced polyurethane composite material is 581×10⁶N・m/kg. The higher the value, the higher the strength that the material can achieve with a lighter "weight". The glass fiber - reinforced polyurethane composite material is like a "light - kung fu master" among "strong men". While ensuring the firmness of the doors and windows, it reduces the building load, makes transportation and installation easier, and also helps the building to be energy - efficient and reduce consumption as a whole. It is definitely an "efficient mechanical undertaker".

III. Thermal Properties - Temperature "Game"

(I) Thermal Conductivity: A "Little Expert" in Heat Insulation

The lower the thermal conductivity, the better the heat insulation performance. The thermal conductivity of aluminum alloy is > 150W/(m・K), and it conducts heat as fast as a "heat conductor". When the sun shines in summer, the indoor environment will quickly become a "steamer"; the thermal conductivity of steel is 36 - 54W/(m・K), and it is not very good at heat insulation either; the thermal conductivity of rigid PVC is 0.14W/(m・K), which has good heat insulation performance; the thermal conductivity of polyester glass fiber reinforced plastic is 0.4W/(m・K); while the thermal conductivity of glass fiber - reinforced polyurethane composite material is 0.114W/(m・K), which is even lower than that of rigid PVC! Using it as a door and window profile is like installing a "heat insulation barrier" for the house. It blocks the entry of outdoor heat in summer and retains the indoor heating in winter, greatly reducing the energy consumption of air conditioners and heaters, saving electricity and providing comfort. It is definitely an "energy - saving model".

(II) Coefficient of Linear Expansion: Stable During Thermal Expansion and Cold Contraction

The coefficient of linear expansion reflects the degree of thermal expansion and cold contraction of a material. The coefficient of linear expansion of aluminum alloy is 2.2 - 2.4×10⁻⁶K⁻¹, that of steel is 1.2×10⁻⁶K⁻¹, that of rigid PVC is 6 - 8×10⁻⁶K⁻¹, that of polyester glass fiber reinforced plastic is 0.7 - 6×10⁻⁶K⁻¹, and that of glass fiber - reinforced polyurethane composite material is 0.5×10⁻⁶K⁻¹. The smaller the value, the less obvious the thermal expansion and cold contraction. When doors and windows use this material, the profiles will not expand and contract significantly with the seasonal temperature changes. There will be no problems such as enlarged gaps leading to air leakage, or profile deformation and jamming. It is always tightly sealed, providing good heat insulation and sound insulation, and the living experience is directly "elevated".

IV. Electrical and Corrosion Resistance Properties - "Bonus Items" for Special Scenarios

(I) Volume Resistivity: Good at Insulation

The higher the volume resistivity, the better the insulation performance. The volume resistivity of aluminum alloy is 2.9×10⁻⁸Ω・m, and that of steel is 9.8×10⁻⁸Ω・m. Both are "good conductors"; the volume resistivity of rigid PVC is 1×10¹¹ - ¹²Ω・m, and that of polyester glass fiber reinforced plastic is 1×10¹²Ω・m, which have good insulation performance; the volume resistivity of glass fiber - reinforced polyurethane composite material is 1.5×10¹²Ω・m, with excellent insulation performance. In scenarios such as thunderstorm weather and near power facilities, using doors and windows made of this profile can effectively reduce the risk of electrical conduction and add an "insulation lock" to the safety of the home.

(II) Corrosion Resistance: "Durability" is the Hard Truth

The corrosion resistance of aluminum alloy and steel is "poor". They will soon rust and be damaged under wind, rain, acid, and alkali erosion; that of rigid PVC is "average", and it will also age and become brittle when exposed to harsh environments for a long time; that of polyester glass fiber reinforced plastic and glass fiber - reinforced polyurethane composite material is "good". Especially for buildings in coastal areas and near chemical enterprises, where salt spray and chemical waste gas erosion are severe, the glass fiber - reinforced polyurethane composite material door and window profiles can withstand the "destruction", have a long service life, do not need to be replaced frequently, saving costs and worry.

V. Summary: Glass Fiber - Reinforced Polyurethane, the "All - round King" of Door and Window Profiles

In comparison, the glass fiber - reinforced polyurethane composite material comprehensively crushes or has significant advantages over traditional door and window profiles such as aluminum alloy, steel, rigid PVC, and polyester glass fiber reinforced plastic in terms of density, mechanical properties, thermal properties, electrical properties, and corrosion resistance. It not only meets the basic needs of door and window firmness, durability, safety, and stability but also excels in energy - efficient heat insulation, adaptation to environmental changes, and protection in special scenarios. It is simply the "all - round king" in the field of door and window profiles!

Whether it is for families pursuing high - quality living experiences or commercial projects focusing on building energy efficiency and long - term use costs, glass fiber - reinforced polyurethane door and window profiles are "treasure materials" worthy of being the first choice. In the future, as the construction industry has higher and higher requirements for performance, environmental protection, and energy conservation, it is believed that this material will shine more brightly in the door and window field and even more construction sub - fields. Let's look forward to more surprises brought by it!

Do you still want to know about the application stories of glass fiber - reinforced polyurethane doors and windows? Such as installation cases or user feedback? Welcome to leave a message in the comment area, and let's dig deep into this "rising star" in the field of building materials together!

Nanjing Jufa New Material Co., Ltd.

E-mail:yuan.cheng@jufa-composite.com

sales3@jufa-composite.com

Add:Building A, Chuangzhi Industrial Park, No. 37 Shenzhou Road, Lukou Street, Jiangning District, Nanjing, China

Web:www.jufa-composite.com

中企跨境-全域组件

制作前进入CSS配置样式

E-mail:

导航下拉添加类名.active

在线客服添加返回顶部

右侧在线客服样式 1,2,3 1

图片alt标题设置: Nanjing Jufa New Material Co., Ltd.

表单验证提示文本: Content cannot be empty!

循环体没有内容时: Sorry,no matching items were found.

CSS / JS 文件放置地