Nanjing Jufa supports the 2025 Transportation Composite Materials Technology Innovation and Application Seminar

2025/08/12

On August 7, 2025, the "2025 Transportation and Composite Materials Technology Innovation and Application Seminar," hosted by the authoritative China Composites Network, grandly opened at the Buckingham Palace Hotel in Changzhou. Nanjing Jufa, a pioneer in industry innovation, was invited to participate, joining industry experts, academic leaders, and corporate representatives to discuss cutting-edge trends in the research, development, and industrial application of lightweight and high-performance composite materials for transportation.

The conference focused on "Green Intelligent Manufacturing, Material Innovation, and the Future of Transportation." Nanjing Jufa showcased its latest technological achievements, showcasing breakthroughs in composite material structure optimization and low-carbon process upgrades through keynote speeches and technical exchanges. A company representative stated, "Relying on core technological innovation, we are committed to providing more efficient and sustainable solutions for modern transportation systems, helping the industry move towards intelligent and green development."

This participation not only demonstrated Nanjing Jufa's leading position in the composite materials field but also, through in-depth interactions with industry, academia, and research, injected strong momentum into promoting transportation technology innovation. Going forward, the company will continue to empower the industry with technology, writing a new chapter in the materials sector for building a strong transportation nation. It came into being against the backdrop of the global transportation industry accelerating its transformation and upgrading towards intelligence, greening, digitization, lightweighting and ultra-high speed. With the theme of "New Ecology of Intelligently Connected Composites, Building a New Future for Transportation", it established an exchange platform for collaborative innovation among "production, learning, research and application". Focusing on general aviation and low-altitude economy, rail transit, automobiles, ships and other transportation fields, it conducted in-depth discussions on the innovation paths and industrial application solutions of composite materials technology.

Composite materials, with their core advantages of lightweight, high strength, corrosion resistance, fatigue resistance, and excellent designability, have become key materials for breaking through industry technical bottlenecks, achieving cost reduction, efficiency improvement, and green development. Their application value in the transportation sector is becoming increasingly prominent. Eighteen professional guests with deep research expertise and extensive practical experience in fields such as aviation, low-altitude economy, rail transit, automobiles, and shipbuilding shared cutting-edge research and systematically elaborated on market-driven practical cases and technical experience in the application of composites in key areas such as fuselages and wings. They also detailed the key links between composite structural design, process optimization, cost control, and market competitiveness. They comprehensively analyzed technology upgrade paths and strategies for adapting to future markets, and provided a forward-looking outlook on new directions in the application of composites in aviation.

In the field of composite materials, Nanjing Jufa New Materials Co., Ltd. is demonstrating its core strength with an innovative posture. As a participating enterprise of listed company Kangda New Materials (Group) and a national high-tech enterprise, Jufa New Materials focuses on the application and development of polyurethane and polyurethane modified resins in the field of composite materials, and has built a complete product matrix covering various types of resins such as pultrusion, winding, RTM/vacuum injection, to meet the needs of diverse scenarios.

Diverse Products, Precisely Adapted to Applications

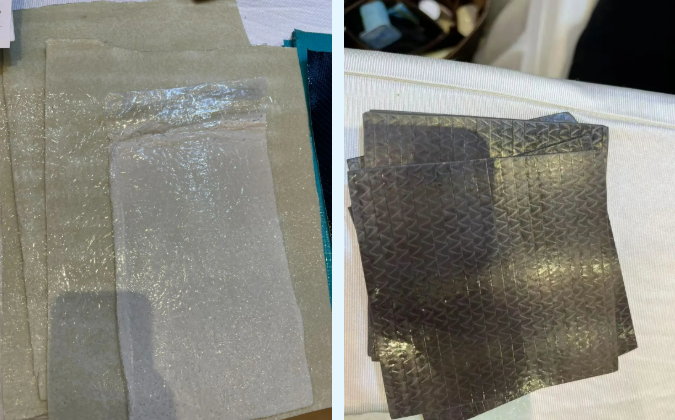

Jufa New Materials offers a rich and diverse product range. Its polyurethane resin series covers pultrusion, prepreg, and winding, among other subcategories. Urepul 2116FR, for example, meets EN45545 HL2 flame retardancy requirements, boasts low viscosity and excellent wettability, making it suitable for large-scale products. Urepul 2117FR is targeted at highway bridge applications, featuring high glass fiber content and high strength. Epoxy resins and adhesives also offer unique strengths, precisely matching applications from rail transit to the power sector.

Technological Leadership, Strengthening Product Advantages

Jufa New Materials offers a wealth of technological highlights across its product lines. The polyurethane pultrusion resin series meets stringent flame retardancy standards, boasts low viscosity and excellent wettability, enabling the molding of large-scale products. Prepreg resins offer long-term storage and excellent mechanical properties, enabling lightweight optimization and meeting the need for weight reduction in transportation equipment. With advantages such as low VOC emissions and environmentally friendly production, Jufa New Materials is taking a leading position in the green manufacturing trend.

Multi-dimensional advantages drive industrial development.

Based on innovative capabilities, we continuously develop and iterate products; collaborate across the industry chain to integrate resources and improve efficiency; and provide high-quality services to precisely meet customer needs. With these three advantages, Jufa New Materials is injecting vitality into the composite materials industry, helping downstream industries break through material bottlenecks. In sectors such as power and rail transit, we ensure safety and efficiency, and promote the industry's move towards high-end and green development.

Nanjing Jufa New Materials Co., Ltd., with its diverse product offerings, leading technologies, and multi-dimensional advantages, has become a "new engine" for innovation and development in the composite materials field. We look forward to collaborating with industry partners to unlock new possibilities through material innovation and build a bright future for the industry!